Science background gives teachers more in-depth information on the phenomena students explore in this unit. Below is an excerpt of the science background information from this lesson on engineering bridges.

Designing Bridges

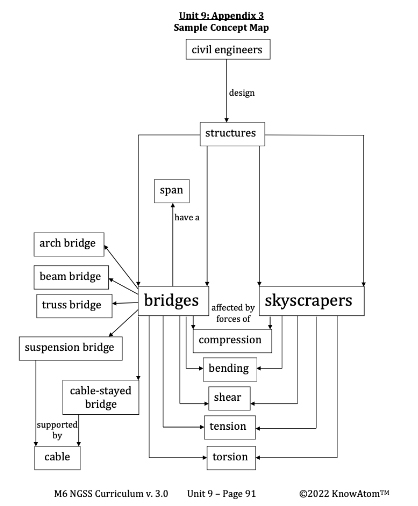

Bridges also play an important role in society because bridges are structures that allow humans to cross obstacles such as valleys or bodies of water. The span of a bridge is the distance it crosses unsupported from below. Like skyscrapers, bridges have to balance all of the forces acting on them. A well-built bridge doesn’t fail because it is made of shapes and materials that balance the forces of tension and compression.

Compression happens on the deck or roadway of a bridge. The weight of people walking or cars driving puts downward pressure on the structure. If a bridge experiences too great a load without enough upward support, it will buckle or break. Tension happens as traffic on the roadway causes the underside of the bridge to become longer. If a bridge experiences too much tension on the bottom without enough support, it will snap.

Different bridge designs work depending on the environment and needs of a particular bridge. For example, the Zakim Bridge, which Miguel Rosales designed in Boston, is a cable- stayed bridge, in which the weight of the deck is supported by a number of cables running directly to one or more towers. Cables are very strong pieces of rope made of steel wire. The cables running directly from the tower to the deck form the distinctive fan-like pattern you see in the Zakim Bridge.

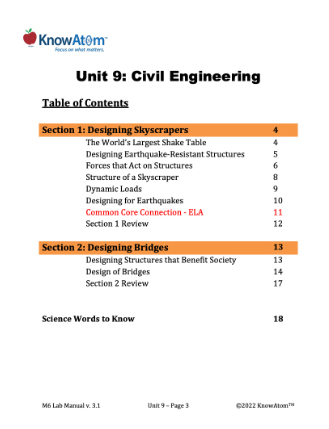

Types of Bridges

Engineers design cable-stayed bridges and a kind of bridge called suspension bridges when they need to span long distances. A suspension bridge is a bridge with long cables that hold up the roadway. The deck is attached to two towers by cables, ropes, or chains. As weight pushes down on the deck, the compression forces are transferred up the cables, ropes, or chains to the towers. The towers then spread out the compression forces directly into the ground.

Tension on the bridge is transferred to the supporting cables, which run horizontally between two anchorages. Bridge anchorages are solid rock or massive concrete blocks that ground the bridge. The tension passes to the anchorages and into the ground.

Engineers design beam bridges to span short distances. The simplest bridge design, beam bridges are designed like a fallen log across a stream. A beam bridge is made up of a long flat piece of material like wood, concrete, or steel. This beam is placed on top of an embankment. Most bridges that go over highways are beam bridges. If the distance gets too long, then the beam part of the bridge can flex and break, so piers are needed to shorten the span for support.

Truss and Arch Bridges

A truss bridge is a modified beam bridge made with many diagonal cross-supports (trusses). Truss bridges add triangles to the shape of a beam bridge to make it stronger. Remember that triangles are the building blocks of many structures because they can bear large loads without losing their shape. Because of their shape, truss bridges use materials efficiently. This makes them economical to build. However, like beam bridges, truss bridges can only span a limited distance.

An arch bridge is another variation of the beam bridge that can span greater distances. The roadway of an arch bridge is held up by a semi-circle curve unsupported by piers. The curved arches transfer the downward weight of the roadway into two end supports called abutments. Arch bridges need strong abutments. The arch design under the roadway means that all of the weight from the compression on the top of the bridge is sent sideways into the abutments. The abutments support loads passing over the top of the bridge. Because of their design, arch bridges experience very little tension.